SPECS

STANDARD

Siemens 840 D-ISL CNC control Unit

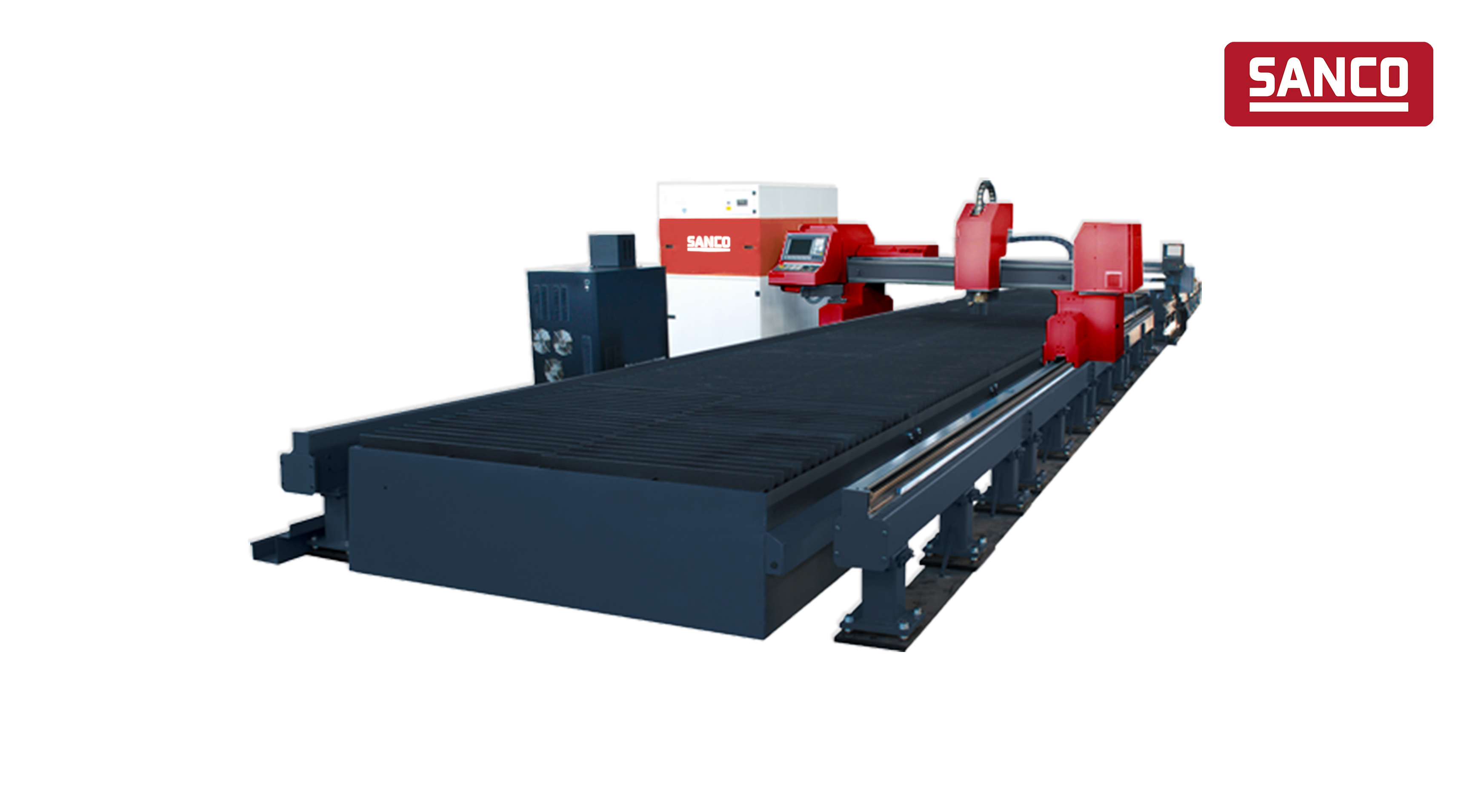

Solid & CNC machined bridge and rail

Robust bridge

CAD CAM Software with Auto nesting

Cutting plate alignment function with Laser diode

Plasma ignition console

Hypertherm Command Torch High Control (THC)

Two side motion control system (backlash reducers + rack / pinion)

AC Digital Servomotors on x and y axes

Marking system through the plasma torch

CNC control outputs/inputs for filter unit

Hypertherm Spare parts, consumables starting kit

High mechanical accuracy to +/- .004 Inches

Very high axis positioning speed of 1365 in/min.

Torch height control travel with ball screw on dual linear guides

Remote diagnostics via Ethernet

Rack & Pinion with linear guide on the z axis (torch height control)

Thick slats on table

Web cam for service

OPTIONAL

Hypertherm Plasma source – choose HPR130XD, HPR260XD or HPR400XD, other non-precision or air-plasma power sources also available

Hypertherm Automatic gas console or Manual gas console

Water table or partitioned downdraft table

Additional plasma torch and power supply (Plasma Torch, Torch Height Control (THC), ignition console)

Additional Oxy-fuel Torch (Oxy-fuel torch, Oxy-fuel torch height control, Oxy-fuel torch height sensor) (maximum 2 oxy-fuel torches)

Bridge preparation for additional torch (plasma or oxy-fuel torch)

Manual torch or plasma beveling system ± 45°

CNC controlled torch or plasma beveling system ± 45°

3D Cutting & Rotator (Contour plasma beveling system)

Safety light barrier

Fault and Program end signal lamp

Air dryer

Hypertherm Arcglide THC Torch Height Control (instead of Command THC) Includes integrated plasma torch breakaway system

Drilling Spindle

Loading & Unloading systems

Special applications